Epilog Fusion Pro Laser Series

Industrial Series – 24, 36 & 48Comprised of the Fusion Pro 24, 36, and 48 all the machines in the Pro Series feature 165 IPS (4.2 m/s) engraving speeds with 5G acceleration, to provide the fastest engraving and quickest job completion possible in the industry.

The Fusion Pro line includes Epilog’s revolutionary IRIS™ Camera Registration System which provides laser operators a real-time image of the engraving table to quickly and accurately position their artwork on even the most uniquely shaped items. The Fusion Pro IRIS System also includes an additional camera to precisely cut jobs with pre-printed registration marks.

| Fusion Pro 24 | Fusion Pro 36 | Fusion Pro 48 | |

| Work Area |

24” x 24” x 9″ (610 x 610 x 228 mm) |

36” x 24” x 9″ (914 x 610 x 228 mm) |

48” x 36” x 12.25″ (1219 x 914 x 311 mm) |

| Laser Options | CO2, Fiber, or Dual Source | CO2 or Dual Source | CO2 or Dual Source |

| CO2 | 60 or 100 watts | 60, 80, or 100 watts | 80 or 120 watts |

| Fiber | 30 watts | --- | |

| Dual Source | - 60 watt CO2 and 30 watt Fiber - 100 watt CO2 and 50 watt Fiber |

80 watt CO2 and 30 watt Fiber 100 watt CO2 and 50 watt Fiber |

120 watt CO2 and 50 watt Fiber |

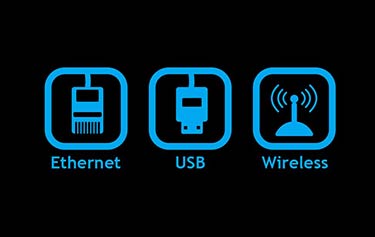

| Laser System Connectivity | Wireless, Ethernet, or USB Connections | ||

| IRIS™ Cameras | 2 overhead + registration | 2 overhead + registration | 2 overhead + registration |

Features & Benefits of Epilog’s Fusion Pro Laser System

The Fusion Pro laser engraving and cutting machines from Epilog Laser combine our top-of-the-line technology and our latest features in a compact desktop format, leveraging over three decades of laser machine design and manufacturing experience to create a powerful and truly modern system.

Highest-Speed Engraving

The Fusion Edge’s 120 IPS engraving speed and 5G acceleration provide the fastest engraving in the industry in a compact format.

IRIS™ Camera Positioning

An overhead camera provides an real-time picture of the working area for accurate artwork placement. Drag and drop your artwork on screen for the fastest work processing.

Touch Screen at the Laser

Select between jobs, auto focus the laser, and rerun jobs at the touch of a button from the easy-to-use touch screen interface right at the laser.

Made in the USA

Proudly designed, engineered, and manufactured in our Golden, CO headquarters at the base of the Rocky Mountains.

Network Your Laser Across Your Business

The Fusion Pro features built-in Ethernet, USB, and Wireless options for networking your laser.

SAFEGUARD™ Features

Keep the mechanics of your laser machine cleaner than ever before with side enclosures, a fully covered x-axis assembly, and covered lens assembly.

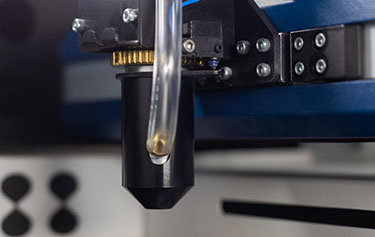

Air Assist

The air assist directs air directed through the cone lens assembly to remove heat and combustible gases from the point of laser contact.

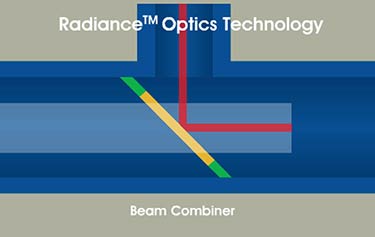

Radiance™ Optics

The beam enhancment technology is standard equipment and provides the highest resolution engraving across the entire table.

CO2 Waveguide Laser Tubes by Epilog

All-metal tube design provides higher beam quality and longer life with low recharge costs.

1 GB Memory in the Machine

Improve job management and data integrity with 1GB of RAM. Save your most run jobs right at the laser.

Long-Life Steel Bearing

A dual block design provides the most rigidity and reduced vibration without the inevitable wobble and replacement of plastic bearings.

Accessories for the Fusion Edge Laser Machines

Rim-Style Rotary Attachment

The Rim-Style rotary attachment adds the ability to engrave bottles, glasses, flashlights, or any other cylindrical item. The Fusion Edge rotary attachment is as easy to setup as placing your product on the rotary, raising or lowering the scissor lift to level the engraving area, and printing to the laser.

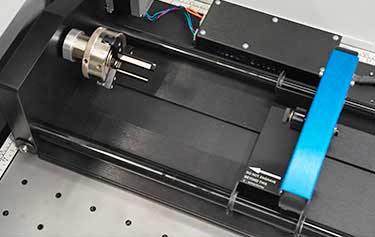

3-Jaw Chuck Rotary Attachment

With the 3-Jaw Chuck rotary, objects are clamped into the device's 3-jaw chuck, allowing you to rotate cylindrical or oddly-shaped items in applications that demand more precise alignment.

Air Assist Pump

Blows a constant stream of air on the cutting area. Epilog's optional Air Assist Pump is available to work with the included Air Assist features of the laser systems. Direct a constant stream of air to your cutting surface to remove heat and combustible gases from the work area.

This high-quality air compressor unit feeds 30 psi of air through the Air Assist structure, giving you the best cutting results available. The rubber vibration-dampening feet reduce the noise level of the compressor, and connection is a breeze with our quick-connect inlet and outlet ports on the compressor and the laser system.

Additional Fusion Edge Lens Options

In addition to the 2.0" lens, we offer special lenses for specific applications.

1.5" Lens: Highest-Resolution Engraving

Although the standard 2.0 inch lens provides amazing detail, our 1.5-inch lens assembly is designed for the highest-resolution engraving and etching of extremely small fonts.

4.0" Lens: Cutting Thicker Materials and Inside Deep Areas

The 4.0 inch lens produces a focused beam over a longer vertical distance, which makes it ideal when engraving within a recessed area of a product, such as inside a bowl or plate. The lens is also used for cutting through very thick materials.

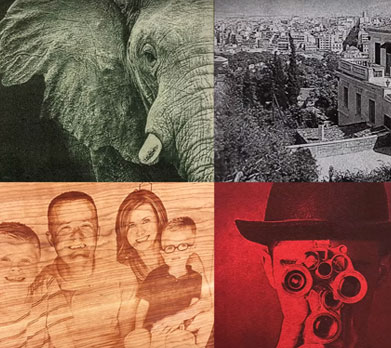

PhotoLaser Plus Software

PhotoLaser Plus takes photo engraving with your Epilog Fusion Edge laser to the next level by easily processing photos for engraving on all types of materials. Epilog Laser has partnered with CADLink to bring you the industry’s best photo processing software: PhotoLaser Plus. The easy-to-use software interface and powerful photo processing tools allow you to create the highest-quality photo engravings in the industry.

Epilog Fusion Edge Technical Specifications

| Fusion Pro 24 | Fusion Pro 36 | Fusion Pro 48 | |

|---|---|---|---|

Work Area: |

24″ x 24″ (610 x 610mm) | 36″ x 24″ (914 x 610mm) | 48″ x 36″ (1219 x 914mm) |

Material Thickness: |

9″ (228 mm) | 9″ (228 mm) | 12.25″ (311 mm) |

Laser Tube Types: |

|

|

|

Laser Tube Wattages: |

|

|

|

IRIS™ Camera System: |

2 overhead + registration | 2 overhead + registration | 2 overhead + registration |

Wireless Connectivity: |

Included | Included | Included |

Included Lenses: |

|

|

|

Optional Lenses: |

1.5″ or 4″ – CO2 | 1.5″ or 4″ – CO2 | 4″ – CO2 |

Resolution: |

Fully-flexible & user-controlled from 75 – 1200 dpi | Fully-flexible & user-controlled from 75 – 1200 dpi | Fully-flexible & user-controlled from 75 – 1200 dpi |

Maximum Engraving Speed (inches/meters per second): |

165 IPS (4.2 m/s) with 5G acceleration. Computer-controlled in .001 increments up to 100%. Color mapping feature links Speed, Power, Frequency, and Raster/Vector mode. | ||

Print Driver & Software: |

Laser Dashboard™, Epilog Job Manager™ | Laser Dashboard™, Epilog Job Manager™ | Laser Dashboard™, Epilog Job Manager™ |

Internal Memory: |

Store multiple files up to 1 GB. Engrave any file size. | Store multiple files up to 1 GB. Engrave any file size. | Store multiple files up to 1 GB. Engrave any file size. |

Operating Modes: |

Optimized Raster, Vector, and Combined mode. | Optimized Raster, Vector, and Combined mode. | Optimized Raster, Vector, and Combined mode. |

Super-Silent Cooling Fans: |

Included | Included | Included |

Motion System: |

Brushless DC Servo Motors | Brushless DC Servo Motors | Brushless DC Servo Motors |

X-Axis Bearings: |

Ground & polished stainless steel, Teflon-coated, self-lubricating bearings. Dual blocks on X-axis for greater rigidity | ||

Belts: |

Advanced B-style double-wide Kevlar precision drive belts. | Advanced B-style double-wide Kevlar precision drive belts. | Advanced B-style double-wide Kevlar precision drive belts. |

Job Trace: |

Included | Included | Included |

Auto Focus: |

Included | Included | Included |

Touch Screen: |

Included | Included | Included |

Status Light: |

Included | Included | — |

Included Table: |

Vector Cutting Table (Grid-Style) | Vector Cutting Table (Grid-Style) | Task Plate |

Drop Down Door: |

Included | Included | Included |

Air Assist Pump: |

Optional | Optional | Included |

Size (W x D x H): |

41.52” x 32.81” x 40.54″ 1055 x 834 x 1029 mm |

53.52” x 32.81” x 40.54″ 1359 x 834 x 1029 mm |

70.6” x 51.3″ x 42.75″ 1794 x 1304 x 1086 mm Pedestal removed: 34” H (863 mm) |

Weight: |

240 lbs (108 kg) | 275 lbs (124 kg) | 650 lbs (295 kg) |

Electrical: |

110 to 240 volts, 50 or 60 Hz, single phase | 110 to 240 volts, 50 or 60 Hz, single phase | 240 volts, 50 or 60 Hz, single phase |

Ventilation: |

350-400 CFM (595-680 m3/hr) external exhaust to outside or internal filtration unit required. One output port, 4″ (102 mm) diameter | Three total ports. Two upper exhaust ports, one lower vacuum table port. Total 735 CFM required. All ports 4” (102mm). | |

Safeguard Features: |

Included | Included | Included |

Class: |

Class 2 Laser Product – 1 mW cW MAXIMUM 600-700nm |

||

Laser Sample Portfolio

Like these creative Samples?

Contact Us

Costa Mesa, CA 92626